BAAP

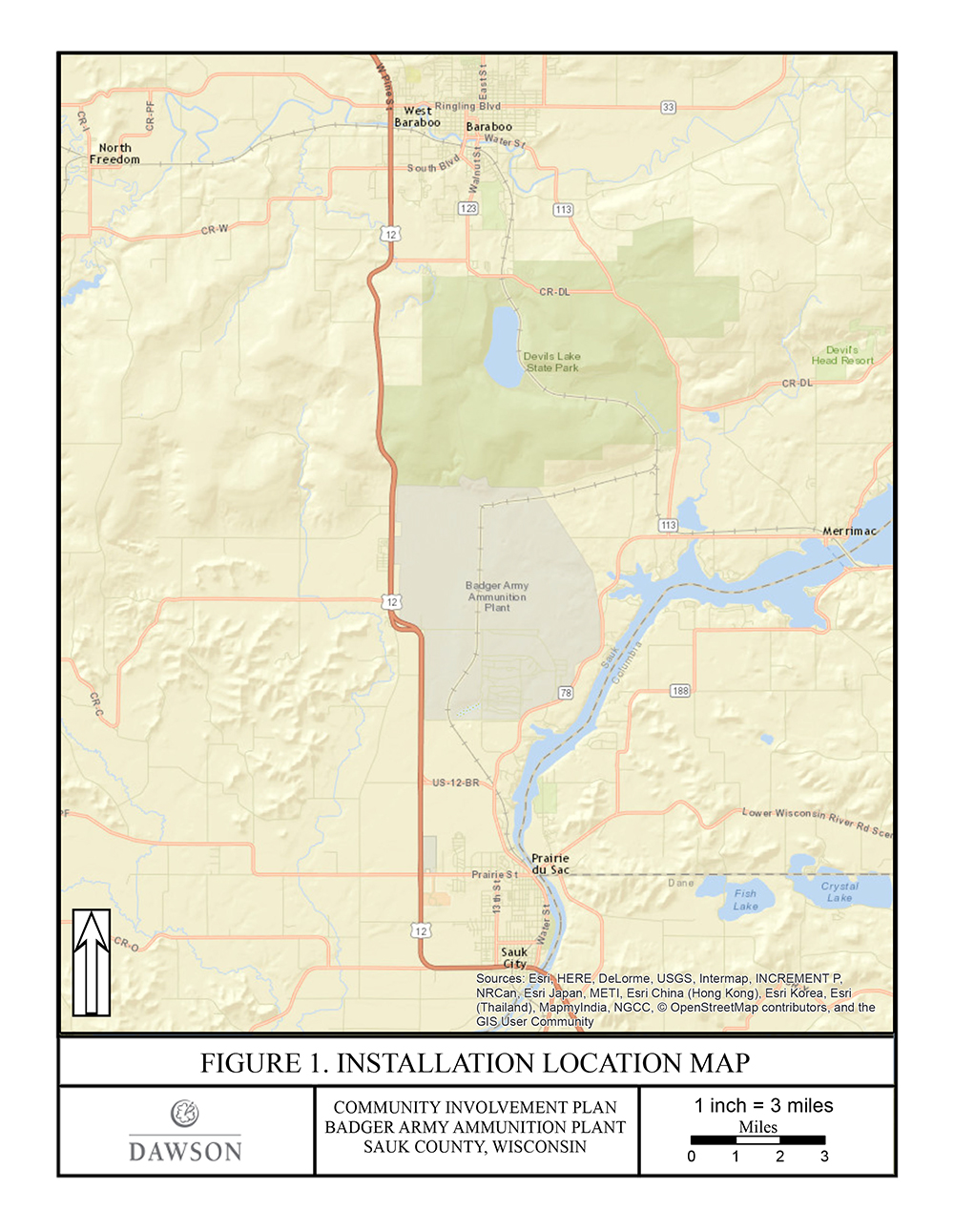

When operating, Badger Army Ammunition Plant (AAP) was located on 7,275.24 acres of land in Sauk County, Wisconsin. The installation was bordered to the north by Devil's Lake State Park; to the east by farmland, State Highway 78 and the Wisconsin River; to the south by farmland; and to the west by U.S. Highway 12. The city of Baraboo is located north of the former Badger AAP, and Sauk City and Prairie du Sac are located to the south. Bluffview, a residential area, is located across Highway 12 directly west of Badger AAP's main gate. There are several unincorporated residential developments east of the former Badger AAP between Highway 78 and the Wisconsin River. The Army has transferred more than 6,740 acres primarily to the U.S. Department of Agriculture; the U.S. Department of Interior (Ho-Chunk Nation) and the State of Wisconsin Department of Natural Resources (Sauk Prairie Recreation Area).